- Machine elements

- Lubricants, aerosols and lubrication accessories

- Cleaning agents and adhesives

- Other products

Technical plastics

Technical plastics are a class of plastics, which differs from standard plastics and engineering plastics primarily by its temperature stability and mechanical properties. In many applications technical plastics gradually replace traditional materials such as wood and metal. The reason for that is an equivalent or even better ratio between weight/mechanical properties and relatively easy processing of the material. The materials vary depending on their mechanical, thermal and electrical properties and also chemical resistance.

The most commonly used standard plastics are: PE and PP, engineering plastics POM, PET, PA, PC, PP-HT and high performance plastics PEEK,PPS,PVDF, PTFE, PPSU, PSU.

- List of standard plastics materials

- List of advanced engineering plastics materials

- List of high performance plastics materials

The wide range of plastics we offer is practically unlimited!

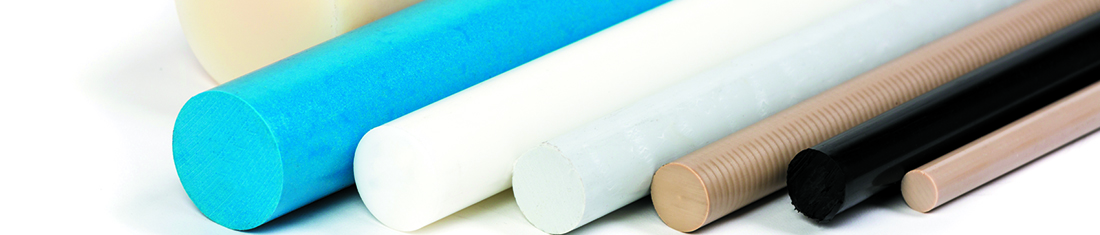

As semi-finished plastics we can offer:

- rods and tubes of various diameters and lengths

- plates of various thicknesses and formats

- foils of various thicknesses

The most popular are:

Many types of plastics are suitable for use in the food processing industry. For that we can provide the necessary certifications.

The most commonly used standard plastics are: PE and PP, engineering plastics POM, PET, PA, PC, PP-HT and high performance plastics PEEK,PPS,PVDF, PTFE, PPSU, PSU.

Choose from Premium brands:

Our experts are on hand to help with any technical support and advice you may require. We will gladly assist you in finding the most appropriate technical solution.