- Machine elements

- Lubricants, aerosols and lubrication accessories

- Cleaning agents and adhesives

- Other products

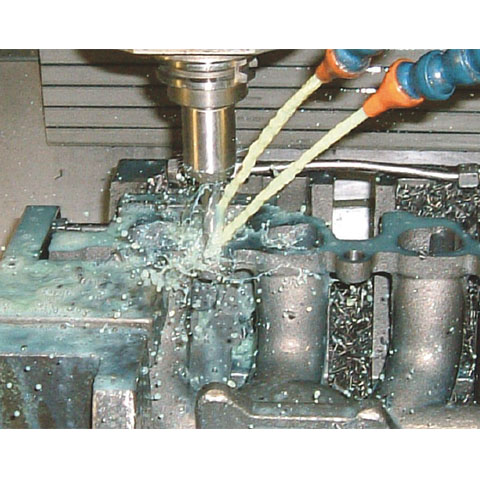

Metalworking fluids

Metalworking fluids are used to cool and/or lubricate metal workpieces when they are being machined, reduce the heat and friction between the cutting tool and the workpiece, remove the fines and chips from the tool being used and the surface of the workpiece, help prevent burning and smoking, and foaming. They prevent rust on machine part and cutters and keep the work piece at a stable temperature.

There are different types of oils that can be used in the metalworking process such as straight oils (also called “cutting or neat” oils), soluble oils (emulsifiable oils – the mixture of oil and water) or oil blends. Choosing the right metalworking fluid depends on the type of manufacturing process, the working material and the tool. In most cases the high lubrication capacity is used in low speed applications, while the high cooling capacity is used in high speed applications.

Standard high-quality metalworking fluids that we use achieve outstanding results.

All metalworking fluids from our programme meet high security and environmental requirements

Choose from Premium brands:

We also supply:

Mobil

Castrol

Aral

BP

Fuchs

Houghton

Catalogues:All catalogue >

Our experts are on hand to help with any technical support and advice you may require. We will gladly assist you in finding the most appropriate technical solution.